NTPEP Field and Lab Reports

And the Winner is… PHOSCRETE!

(Whatever the Weather)

F1-HC 2021 Ohio test deck inspection after 2 years

F3-VO freeze/thaw image after 300 cycles

AASHTO’s Product Evaluation and Audit program (formerly NTPEP), just published the two-year field inspection on Phoscrete F1-HC and F3-HC, and also published the 2023 lab reports on Phoscrete F3-HC and F3-VO. Highlights follow:

2021 Ohio Test Deck Report

- Phoscrete Formula 1-HC

- Phoscrete Formula 3-HC

In October 2021 the Phoscrete Team travelled to Bowling Green, Ohio for the NTPEP test deck installation. Inspections were performed by ODOT personnel after one year and again after two years. The final report for Phoscrete F1-HC and F3-HC reported zero delamination and zero mid-panel cracking.

2023 Lab Test Highlights

- Phoscrete Formula 3-HC (Horizontal/Castable)

- Phoscrete Formula 3-VO (Vertical/Overhead)

In July 2023, Phoscrete submitted our two Formula 3 products (F3-HC and F3-VO) to NTPEP. Results were published on the NTPEP DataMine in January 2024.

Set Time

ASTM C403

Phoscrete’s new F3 formulas achieve final set in less than 25 minutes, delivering on our objective for durable materials with a longer working time for large volume repairs in warm temperatures. F3-HC is typically traffic ready in 2 hours.

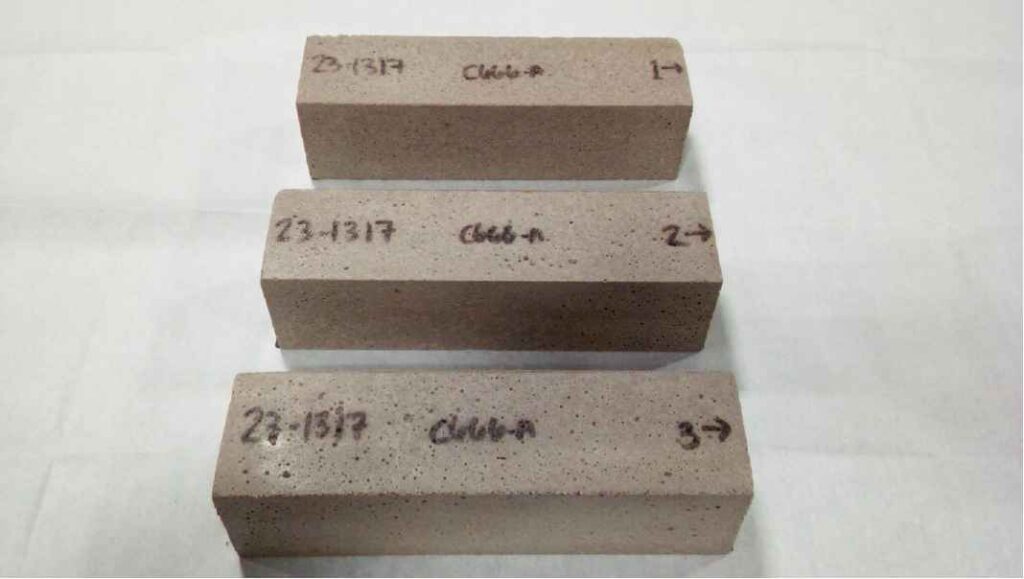

Freeze-Thaw Resistance

ASTM C666 (Procedure A)

Phoscrete’s new F3 Formula withstood this aggressive lab test with >99% durability, no mass loss, and no change in surface condition. Phoscrete F3 Liquid Activator jugs include a dose of Phoscrete Endure for ease of mixing and placement. An additional jug of Endure is provided with F3 as a curing component for added durability.

Length Change

ASTM C157

Both F3-HC and F3-VO reported extremely low dry cure shrinkage and minimal wet cure expansion. In combination with Phoscrete’s high bond strength, These tests support our field experience of no delamination, cracking, or cold joints.

Read the full reports at NTPEP DataMine (login required).

Our latest technical data guides can be found on our website:

- TDG Phoscrete Formula 1-HC (Horizontal/Castable)

- TDG Phoscrete Formula 3-HC (Pail/Pump)

- TDG Phoscrete Formula 3-VO (Hand-Pack/Spray)

Key Differences Between F1-HC and F3-HC

As always please contact us to find out which Phoscrete formula is the best fit for your specific applications.

| Property | F1-HC | F3-HC |

| Final Set @ 70°F | 12 min | 24 min |

|

Traffic Ready @ 70°F |

< 1 hour |

< 2 hours |

|

Working Temperature* |

> -5°F |

> 32°F |

* Working Temperature is based on the freezing point of the activator.

- Phoscrete recommends installing F3 in temperatures > 50°F (10°C).

- In hot temperatures cool Phoscrete Activator on ice for extended working time.

- Use Phoscrete Slow-Set Admix with F3 to extend working time when pumping or spraying.

- In cold temperatures, use Phoscrete Fast-Set Admix with F1 to accelerate set time.

Try Phoscrete MPC Products Today

Haven’t used Phoscrete recently? Now is the perfect time to reach out and learn if Phoscrete is a good fit for your concrete repair projects!

Do you have any questions or require further assistance? Please contact your Phoscrete Sales Engineer, fill out our contact form, or chat with us here on our website.